All our machines are custom made to suit the environment, of course there is a minimum size required.

A soft mud brick press with automatic mould circuit Clay is prepared and mixed with water, in readiness for the production process The clay is pressed directly from the mixer into the moulds. In this (NL) factory each mould makes 8 standard bricks 8 bricks are pressed each cycle. The “circuit” has fully automatic washing and sanding of the mould boxes The moulds must be washed clean, then sanded each cycle. Standard or special shapes are all possible.

Brick production up to 5000 bricks per hour, depending on the size of the mould.

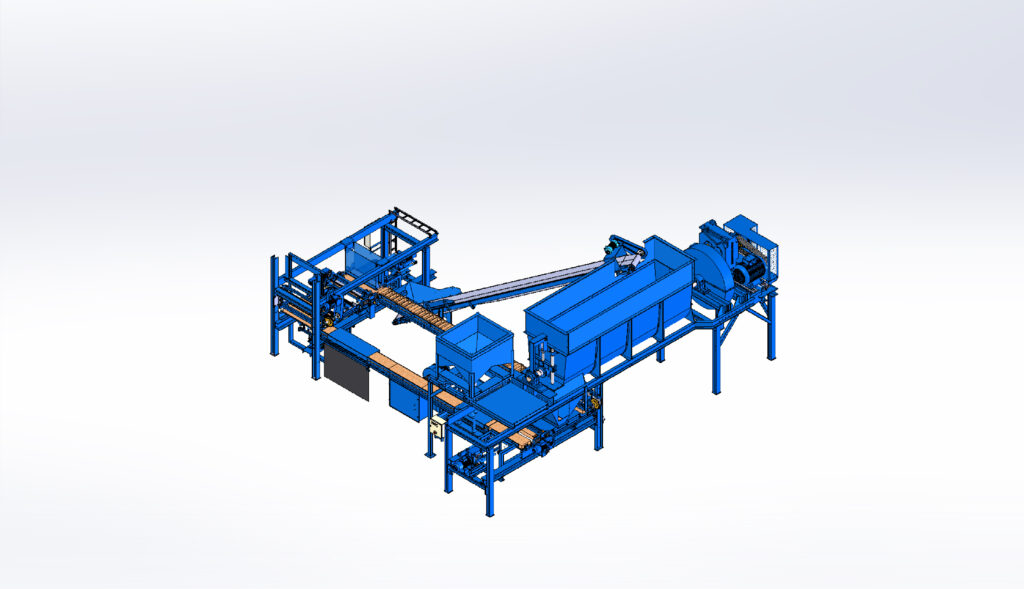

A soft mud brick press with automatic mold circuit. Clay is prepared and mixed with water, ready for the production process. The clay is pressed directly from the mixer into the molds, or thrown with the Hubert system. In this (AL) factory, 14 standard bricks are made per mold. 14 stones are pressed per cycle. The “circuit” has fully automatic washing and sanding of the molded boxes. The molds must be washed clean and then sanded each cycle. Standard or special shapes are all possible.

Brick production of up to 7560 bricks per hour, depending on the size of the mold.

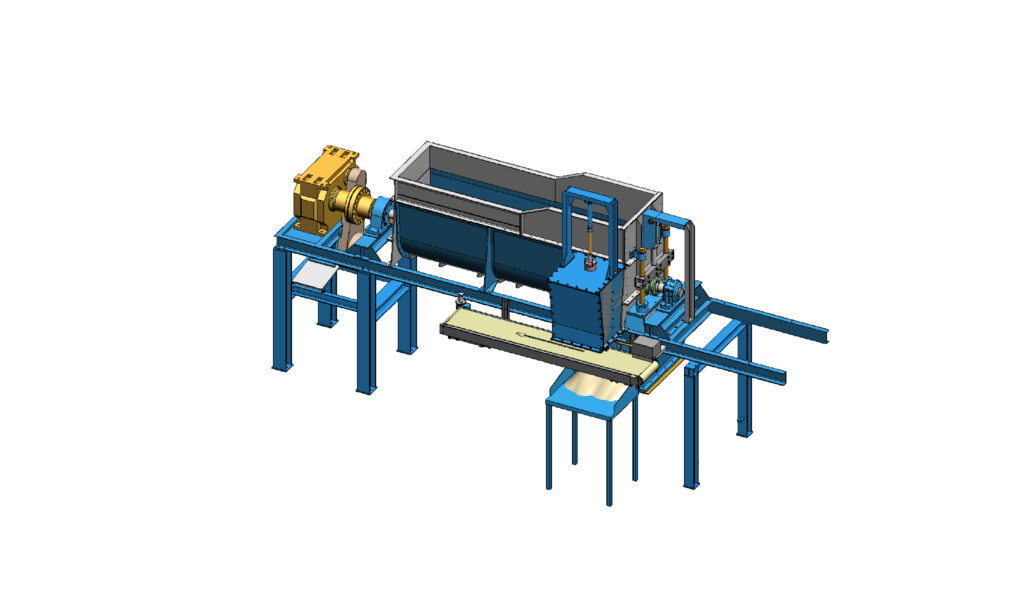

A soft mud brick press with automatic mold circuit. Clay is prepared and mixed with water, ready for the production process. The clay is pressed directly from the mixer into the molds. In this (TR) factory, 8 standard bricks are made per mold. Each cycle, 8 stones are pressed or thrown by a Hubert system. The “circuit” has a fully automatic washing and sanding of the mold containers. The molds should be washed clean and then sanded each cycle. Standard or special shapes are all possible.

Brick production up to 5000 bricks per hour, depending on the size of the mold.

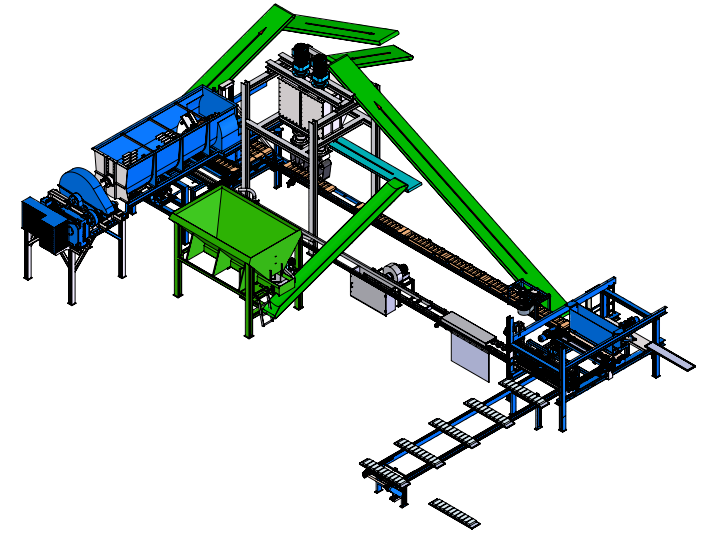

A soft mud brick press with automatic mold circuit. Clay is prepared and mixed with water, ready for the production process. The clay is pressed directly from the mixer into the molds. In this (EN) factory, 8 standard bricks are made per mold. Each cycle, 8 stones are pressed or thrown by a Hubert system. The “circuit” has a fully automatic washing and sanding of the mold containers. The molds should be washed clean and then sanded each cycle.

Standard or special shapes are all possible. Automatic filling of drying racks and transfer to drying chambers.

Brick production up to 5000 bricks per hour, depending on the size of the mold.

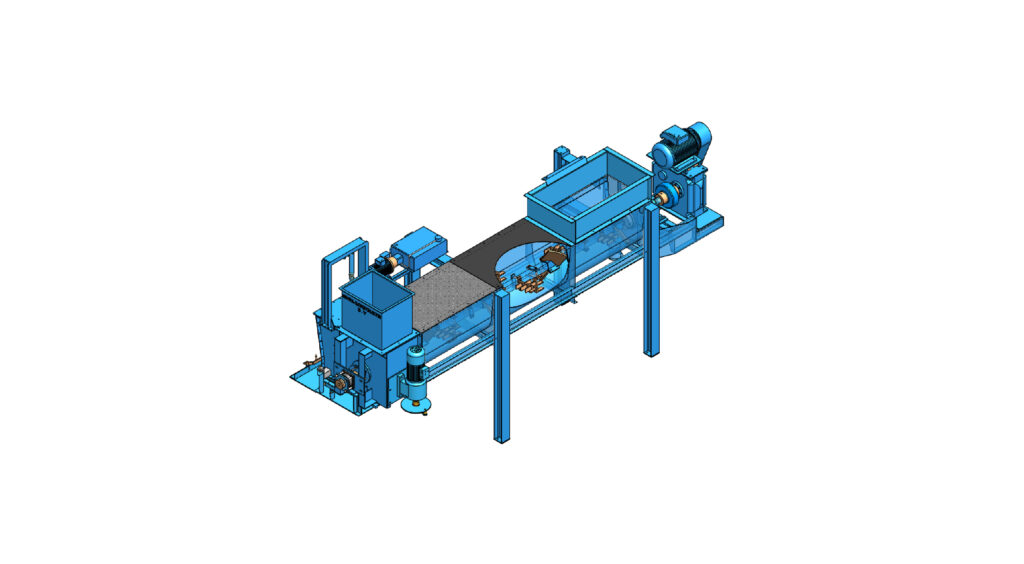

Clay clot mixer press has been developed for small quantities of hand-formed bricks.

It is possible to install a transport circulation system whereby the excess clay is transported directly back to the mixer.

Manual mixer press for making small quantities of bricks. The mold must be sanded and placed manually. After pressing, the mold must be emptied manually.

It is also possible to make clay clods for using hand-moulded bricks.